Description

2025 Husqvarna TE 300

Go where few have gone before with the TE 300. For 2025, the machine of choice for hard enduro riders worldwide receives several technical upgrades to re-affirm its position at the top of the 300 cc 2-stroke category. New Brembo clutch and brake systems raise the performance and reliability while ProTaper handlebars, Dunlop tires, and a Twin Air filter headlining the competition-focused components. By retaining its light, agile chassis, and plush WP XACT suspension, the superior rideability of the TE 300 is never in question.

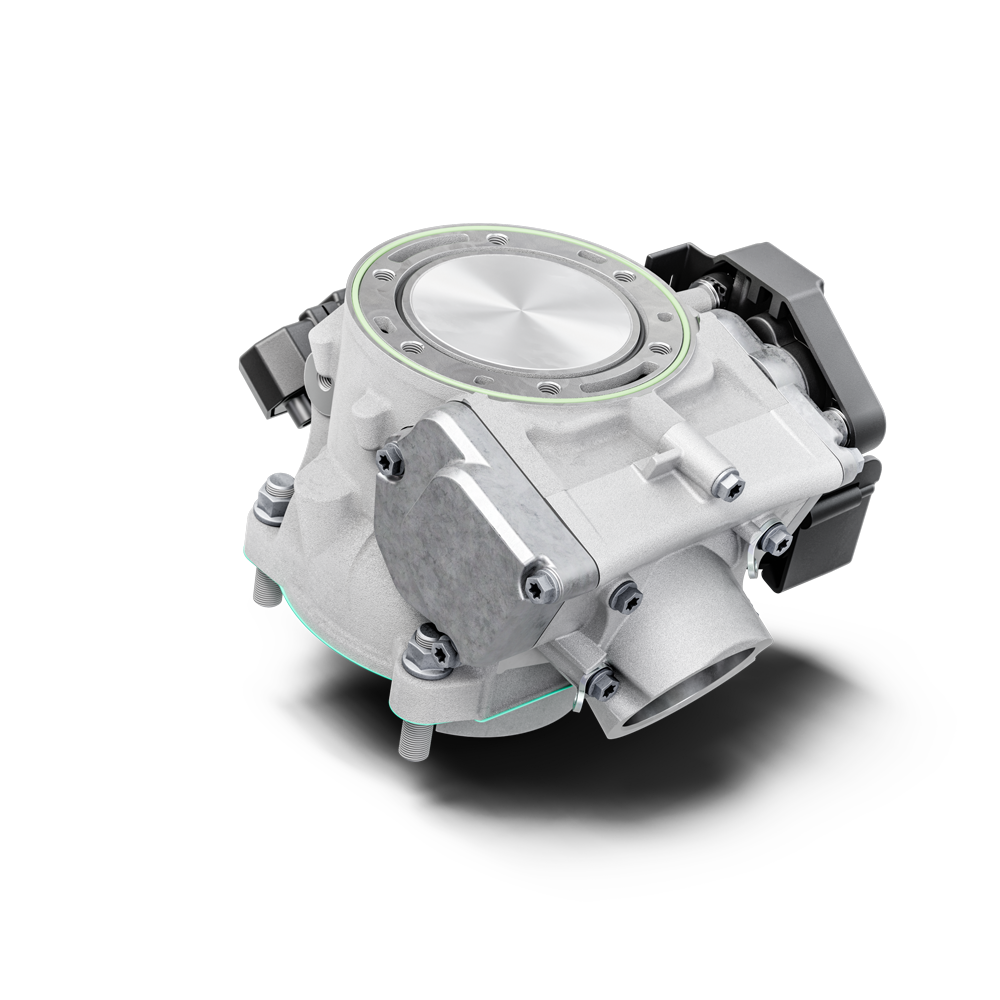

Engine

Delivering class leading power, the TE 300 engine is built with maximum performance in mind. Thanks to the Throttle Body Injection, the engine delivers impressive torque while maintaining its high revving two-stroke character to offer all riders a versatile power delivery. Designed to be compact to reduce overall weight, the engine tips the scales at just 54.2 lbs. Additionally, the shaft arrangements inside the TE 300 engine are precisely positioned for greater mass centralization while a counter balancer shaft reduces vibration.

.

Cylinder

With the introduction of Throttle Body Injection on the TE 300, the 72 mm bore cylinder now features an innovative electric exhaust control system, which manages the opening of the lateral exhaust ports after the main exhaust port opens for maximum power delivery. Together with a machined finish on the upper contour of the exhaust port that ensures accurate port timing, unrivalled engine performance is assured.

Throttle Body

The TE 300 uses 39 mm throttle body with dual injectors positioned to optimize flow for more immediate throttle response and exceptional rideability. Idle is controlled by the throttle valve, with one low load injector and one top feed injector ensuring maximum performance. Additionally, a Throttle Position Sensor offers reliable cold starting with the throttle valve now pivoting on ball bearings for smoother throttle action.

Crankcase

Designed to be low weight without sacrificing stregth or reliability, the new crankcases are made using a high-pressure die cast production process to create a thin-wall desing. To centralise engine mass, the shaft arrangements are precisely positioned to harness rotating masses at the ideal centre of gravity.

Exhaust

Tailored specifically for the TE 300 using an innovative 3D design process, the header pipe ensures unrestricted performance and offers improved ground clearance to reduce the risk of impact damage out on the trail. The silencer also features an aluminum mounting bracket and advanced construction for excellent noise damping and weight saving.

Frame

The proven chromium molybdenum steel frame is refined for 2024. A new shock mounting, which is no longer connected to the main tube, significantly improves the anti-squat behavior of the chassis. With optimized wall thickness in high-stress areas improving reliability, the frame continues to offer advanced geometries and flex characteristics aimed at providing unparalleled rider feedback, energy absorption, and straight-line stability. The frame is complete with a premium metallic blue powder coating with redesigned standard frame protectors offering improved grip in all conditions. Additionally, the redesigned and robust skid plate offers exceptional frame and engine protection.

Bodywork

Adorned with clean, Swedish-inspired graphics, the bodywork is designed to allow riders to perform at their best for extended periods of time. A flat seat profile offers unrestricted movement with a new, high grip cover ensuring riders stay firmly in place under hard acceleration. Above the side panels, recessed pockets allow for the machine to be lifted and moved, which is particularly beneficial for those competing in extreme enduro events.

Fuel Tank

A 2.24-gallon fuel tank integrates neatly with the ergonomic bodywork and features a robust rubber cushion beneath it to hold the tank in place and protect the frame from wear. The one-piece fuel pump design and integrated filter allows the tank to be emptied further, which is particularly beneficial during longer events. For durability, the external fuel line is specifically routed to make it less exposed and susceptible to damage.

Radiators

Manufactured from high-strength aluminum, the radiators are designed using Computational Fluid Dynamics (CFD) to channel air through them in the most effective way. A large center tube channels coolant through the frame to reduce pressure at this point in the system for a more consistent flow. An internal thermostat enhances reliability while the radiator cap features a bayonet style closure for a secure fitment.